So, I finally have some actual real, useful data captured!

This last weekend was a bank holiday weekend in the UK and so we went camping down in Weymouth by the sea. We drove down Friday evening and left Monday afternoon. So we were there for three nights. There was no electrical hookup, so we would be relying on the batteries alone. We've stayed that length of time before just on batteries, but I've never been able to instrument how the batteries were doing and was never very sure of how well they were working. My gut feeling was always that we were running dangerously low at the end.

Since then I have re-done the main battery cabling and built some new bus bars, and so I think the connections are much better. I've also got a much better ground connection as well, using a M8 rivnut into the van floor rather than just a 3mm pop rivet. I've also dropped one battery. I originally had 3 x 115Ah batteries, but I feared one (at least) was dead and removed it. So I'm now just running on 2 x 115Ah batteries.

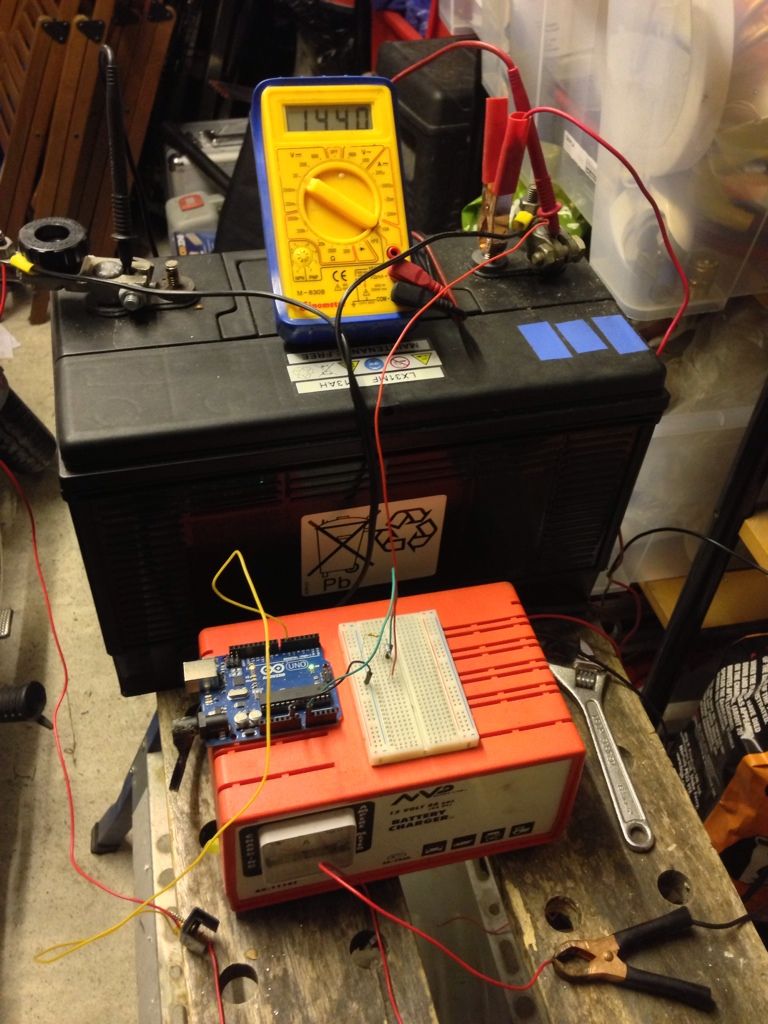

The Arduino battery monitor was set to record voltage, current and temperature every second to an SD card. The temperature was measured using a one-wire temperature probe that was taped to the negative terminal of one of the batteries.

Before I get on to the results.... let me just say, I can now understand why so many battery monitors out there give misleading readings, and why some of the papers I read on estimating battery capacity are so complex... the graph results are so complex. The end goal I'm aiming for here it to somehow reduce the mass of numbers I've accumulated into just one. A current battery capacity... e.g. 85%. Maybe even some kind of runtime until empty. But when you see they graphs you will realise why that is going to be so difficult.

|

| Voltage and Current over Time |

You will want to click on the image to enlarge it. It shows the raw voltage and current captured over the 3 days.

So I should probably talk through the top graph as to what exact was happening.

Thu 21:00: graph starts. Data is being captured, there is no solar charging as it is night time, and the compressor fridge is switched off. Nice smooth line with the voltage dropping slightly over time as surface charge from solar earlier that day drops off. Settles around 12.9V.

Fri 06:00: Sun comes up, voltage rises to a peak of 13.3V and current increases slightly due to charging from solar panel. We are on float charge.

Fri 08:00: I switch the compressor fridge on and load it with food for later, I also drive it from outside the house to the parking spot around the corner (so warden won't ticket me). You see a very brief spike in voltage as the engine charger kicks in taking the voltage up to 14.6V. The compressor fridge brings the voltage down and the graph starts to get 'messy'. The compressor on the fridge kicks in every 5 minutes and runs for a few minutes. This is what causes the min and max on both the voltage and current lines.

Fri 15:00 The sun comes out and the solar panel is now putting in as much as being taken out by the compressor fridge. You can see the highs of the current (red) line going above zero. The voltage is also going up to highs of 14.5V. The voltage oscillates a lot due to both the compressor fridge and also passing clouds.

Fri 18:00 I start the engine and we drive down to Weymouth. The drive is approx 2.5 hours. You can see the engine charge has kicked in and bringing the voltage max up to 14.7V. The current spikes up and down, but you can see a core downward trend on the current during the charging to finish at about 2A. As the battery is fairly well charged still and the solar panel kept up with the demand of the compressor fridge over the day, this is what I would expect. The engine charger doesn't need to put much charge into the batteries.

Fri 21:00 We are at the campsite and the sun has now pretty much gone down. The solar panel is not generating any power and the engine is off. You can see a baseline max current of 0A. ie, nothing. And a baseline minimum of around -4A. That is the compressor fridge drawing 4A of current from the batteries. You can see the voltage also drops down to a baseline max of around 12.8V and a min of around 12.6V. When the compressor fridge runs, the draw on the batteries causes the battery voltage to drop. You can see a slow downward trend overnight as energy is drawn from the batteries.

Sat 06:00 The sun starts to rise and you can see both the voltage and current increase.

Sat 10:00 A sudden drop for a while on both voltage and current. This is due to me unplugging the solar panel to see what the battery would settle to with no input.

Sat 11:00 The current rises following an arc as the sun moves across the sky. It was a pretty sunny day with no clouds.

Sat 15:00 The solar panel has brought the voltage back up to a peak of 14.4v. So we could infer from this that the batteries have managed to reach full charge again (minus a 'topping off' charge or absorption phase').

Sat 17:00 Sudden drop in current and voltage. I've started up the Webasto diesel heater to heat some hot water for a shower. This heater has a pump that draws quite a bit of current, plus the glow plug for the heater which draws a lot to start with.

Sat 20:00 The sun is down, the van batteries are now losing their surface charge and again we start a night of the compressor fridge running and energy being drawn from the batteries. Once the surface charge is lost you see a slow downward trend on the voltage ending with a baseline max of around 12.7V. You see a number of very big downward current spikes to around -15A which I think may be that the reading was taken exactly as the compressor kicked in and that is the inrush current on the compressor motor.

Sun 06:00 The sun starts to rise again and the solar panel starts to bring the current and voltage up. We spent the day at the beach. It was a glorious sunny day. You can see the voltage and current rise and fall with the sun.

Sun 09:00 Short sharp dip as I fire up the heater to heat some water for a shower.

Sun 18:00 Another short dip as I fire up the heater again to make sure there is hot water to wash salt and sand of a very happy but tired 2 year old daughter who spend the day playing on the beach.

Sun 20:00 The sun is down, the surface charge is coming off the batteries and the current is alway negative as there is no charge source. Another night with just the compressor fridge drawing energy. The voltage drops to a baseline max of around 12.65V and a min of around 12.48V.

Mon 06:00 Sun is rising and current and voltage increase.

Mon 09:00 Heater on again for a bit for hot water to wash up.

Mon 14:00 We leave the campsite and start to drive home. You can see the engine charger kick in and take the current up to a peak of around 9A. Considering the charger can go up to 50A this seems a bit low, but I guess the batteries will determine how much current they will accept. The voltage is up to around 14.7V. The engine charger takes a break every 20 minutes to let the vehicle battery get some charge and to assess the charge situation. That is why there are voltage drops as we go along. You can see a steady downward trend on the current as the batteries charge and reduce how much they accept. This finishes at around 2A.

Mon 17:00 We are home. The van is parked up. For a while the compressor drieg keeps running until I get out to empty the fridge of things we didn't eat, and then switch it off. You see a small tail at the end of smooth line. The current is 0A and the voltage is around 13.12V.

So the big question is what does that all mean? How did the batteries hold up? How much charge did we take out of them? How long could we have stayed there before the batteries 'ran out'? Did the batteries get fully charged by the time we got home? So many questions! Well I'll answer them in the next blog post as I need to go get some real work done first!